Inclinometer Accelerates Platform Alignment

Inclinometer with fusion technology improves the alignment of the platform in blow molding machines

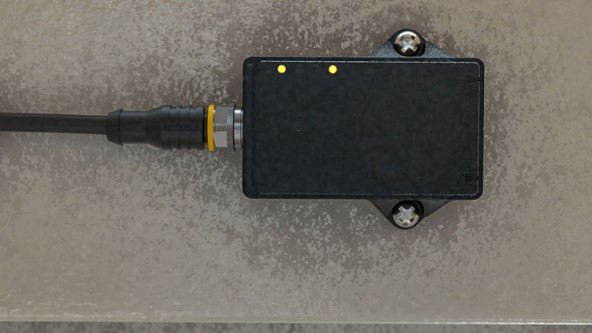

Beatles or Stones? FC Barcelona or Real Madrid? Pasta or pizza? Why not have the best of both worlds? The developers of the B2NF inclinometer agreed, and fused the two measuring methods MEMS and Gyroscope for faster signals despite vibrations. Learn how the sensor improves platform alignment in blow molding machines in our application example.

Your Benefits

- Faster process speeds thanks to dynamic sensor signal

- Higher plant availability thanks to exclusion of platform tilting

- Precise assembly without additional devices thanks to integrated LED spirit level

- Integrated status monitoring using IO-Link

In blow molding machines, the platforms on which the workpiece is blown must be raised or lowered during product changes. Spindle drives are usually used for this purpose. However, temperature drift can cause deviations in the stroke of the spindles. In this case, an inclinometer on the workpiece platform helps to guarantee horizontal alignment and thus avoid costly tilting of the platform.

Fusion technology enables inclination measurement with unrivaled dynamics

Unlike alternative inclinometers, the Turck B2NF can output a signal with high dynamics and precision despite vibrations and shocks. The sensor achieves this by fusion of two sensor signals: It combines a classic MEMS measuring cell with a gyroscope — a combination familiar from smartphones and drones. The result is more precise signals that are output faster. This is made possible by the absence of signal filters, usually at the expense of the dynamics.

Higher travel speeds = higher cycle rates

So far, many machine builders have limited the travel speeds of the platforms due to the weak dynamics of the inclinometers. With the fusion inclinometer, use in fast control loops for dynamic platform leveling is now also possible.

Fastest IO-Link interface

The sensor outputs its signal via IO-Link-COM3 – the latest and fastest version of the digital interface. Additional information on the operating hours of the sensor or its ambient temperature can also be output via IO-Link. This information helps to permanently monitor the machine status in terms of condition monitoring systems.

LED spirit level for simplified installation

The inclinometers are often not yet fully set up in the IO-Link master when they are mounted. Previously, the sensor had to be mounted either using a spirit level, or its signal was later set to zero by the controller. The B2NF has a patented LED spirit level, which uses its flashing frequency to indicate the horizontal position of the sensor as soon as it is supplied with power.

- Automotive

- Level Measurement in Dip Coating Line

- Level Control in Central Lubrication System

- Quality Assurance on the Gluing Robot

- Tilt angle sensor accelerates platform alignment

- Motor Control with Condition Monitoring

- IP67 Hybrid Module Processes Safety Signals

- Decentralized monitoring of cooling stations

- Robot welding cells networked with Ethernet

- Monitoring the cooling circuit on welding clamps

- Flow monitoring in drum washers

- Sheet Metal Thickness Measurement

- Condition Monitoring of Motors as a Retrofit

- Cloud-based Level Monitoring

- Press Shop

- Body Shop

- Paint Shop

- Final Assembly

- Tier 1

- Powertrain

- Body Detection in Automobile Production

- Area Guarding for Robotic Cells

- Item-level Detection with UHF RFID

- Supply of cooling lubricant in machine tools

- Controlling hydraulic pressure in pressing plants

- Measuring process pressure on scissor lifts

- Automotive Welding Tip Inspection

- Manual Load Weld Cell

- Detecting Black Parts on Black Door Panel

- Moonroof Detection

- Long-Range Inspection in Automotive Assembly

- Rubber Washer Detection on Engine Block

- Engine Block Part-In-Place Detection

- Electric Vehicle Detection

- Vehicle Detection in a Self-Serve Car Wash

- Success Stories

- Laser Sensor Detects Black Bumpers in Assembly Cell

- Decentralized Safety Technology for Modular Production

- Modular Conveyor System

- RFID and I/O modules for Safe Tool Changes

- RFID Guides AGV in Suspension Production

- IO-Link Wired Silencer Production

- Workpiece Carrier Identification in Rear Vent Production

- Weld Nut Sensing

- RFID Traceability

- RFID in Engine Production

- Bumper Production with Identification

- Solutions for Paint Shops

- Welding and Assembly Sensors

- Angle Sensors for Assembly Systems

- Tool Identification

- Pick-to-Light for Bumper Assembly

- RFID Identification of Injector Nozzles

- RFID in the Body Shop

- Ply Orientation Inspection

- IO-Link Eases Differential Gear Production

- Chemical

- RFID Control of Tube Connections in the Ex Area

- Ethernet Signal Connection in the I&C Room

- Ethernet-based Automation of Modular Skids

- Ex Isolation in Modular Process Plants

- Detection of Pigs

- Remote Signal I/O

- Remote Tank Level Monitoring with DX70

- Easy Connection of Field Devices

- Signal Processing with System I/O in the Control Cabinet

- Signal Separation with Interface Technology in the Control Cabinet

- Identification of Hose Connections

- Efficient Monitoring of Cabinets in the Field

- Monitoring of Quarter Turn Actuators

- Planning and Assembly of System Solutions

- Success Stories

- I/O System Excom Creates Space in the I&C Rooms

- Zone 2 and 22 RFID

- Efficient Testing Control

- Intrinsically Safe Field Communication

- Process Control System Partnership

- Hazardous Area Remote I/O

- Dual Valve Position Feedback

- Flexibility with Fieldbus

- Asset Management with Remote I/O

- Correct Positioning with RFID in Carbid Production

- Fast conversion in restricted space

- Energy

- Food and Beverage

- Condition Monitoring of Control Cabinets

- Dough Height Inspection

- Condition Monitoring in Storage Rooms

- Dough Thickness Control in Rolling Machines

- Identification of Food Containers

- Leading Edge Detection of Packages with a Thin, Flexible Edge

- Detection of Valve Position

- Container Check

- Date/Lot Code Verification

- Detection of Pipe Elbows

- Identification of Chocolate Moulds

- Detecting Refrigerated Breakfast Rolls on a Multi-Lane Conveyor

- Barcode Reading on Pallet

- Success Stories

- Grist for the Mill

- Decentralized Control Modules in Coldstore

- Track and Trace in Meat Production with RFID

- Contact-free Encoder in Potato Production

- UHF RFID in Food Distribution Center

- RFID for Chocolate production

- Distributed I/O for Food Equipment

- Remote I/O for Distilleries

- RFID and Autoclaves

- IP67 Power Supplies for Conveyors

- Transparency in Chocolate Manufacturing

- Identification in Food Product Storage

- Cap Orientation Verification

- Clear and Tipped Bottle Detection on Depalletizer

- Clear Plastic Bottle Detection

- Food Packaging Label Inspection

- In-Line Accumulation on Single Filer

- Logistics

- Decentralized Muting of Electro-sensitive Protectice Equipment

- I/O Blocks Control Roller Conveyor Modules

- Container Check

- Fast Tag Detection at Warehouse Gates

- Item-level Detection with UHF RFID

- Loading Dock Occupancy Monitoring

- Preventive Maintenance on Conveyor Belts

- Wireless Forklift Signaling

- Detection of Transport Containers

- Level Detection in Vessels

- Identification of Cryovessels

- Reach Stacker Status With Bright Lighting Indicators

- Identification of Mobile Containers with Handheld Devices

- Identification of Food Containers

- Tier 1 – Bumper Identification

- Condition Monitoring in Storage Rooms

- Collision Protection on Reach Stackers

- Success Stories

- Decentralised UHF RFID Solution

- Contact-free Encoder in Potato Production

- Decentralized Control Modules in Coldstore

- Speed Control via Radar Sensor QT50

- IP67 Power Supplies for Conveyors

- Modular Conveyor System

- RFID Solution for Warehouse

- RFID Guides AGV in Suspension Production

- RFID Identifies Pharmaceuticals

- UHF RFID in Food Distribution Center

- Autonomous Parking Assistance for Trucks

- Mobile Equipment

- Loading Dock Occupancy Monitoring

- Automatic Slope Compensation

- Monitoring Railcars Wirelessly

- Distribution Lines for Field Sprayers

- Reach Stacker Status

- Angle Measurement on a Field Sprayer

- Determining the Boom Angle Position

- Material Flow Monitoring on a Combine Harvester

- Vehicle at Loading Dock

- Equipment Compartment Illumination on Fire Engines

- Wireless Forklift Signaling

- Two-Axis Tilt Measurement on a Combine Harvester

- Collision Protection on Reach Stackers

- Success Stories

- Access Control with RFID System

- Selective Asparagus Harvester

- Position Measurement with RFID and Encoder

- Speed Control via Radar Sensor QT50

- RFID Guides AGV in Suspension Production

- Block I/O Modules on Super Yacht

- Wear-free Encoder on Hopper Dredger

- I/O for Dust Suppression

- Cabinet Cooling

- Quick Disconnect Connectivity

- Automation Solutions for Extreme Cold

- Remote I/O for Cranes

- Rugged Heavy Metal Lifting

- Rollercoaster Positioning

- Mobile Machinery Solutions

- Exact Height Positioning

- Predictive Maintenance of Machine Parts at Port-Based Coal Conveying Facility

- Critical Angle Sensing

- Angle Sensor Detects Platform Lift

- Oil and Gas

- Packaging

- Decentralized RFID Package Verification

- Identification of Printing Color Cartridges

- Container Check

- Reliable Operation of Machines

- Monitoring of Caps in Filling Lines

- Monitoring Changeover Processes

- Identification of Test Bottles

- Level Monitoring of Ground Coffee

- Box Insert Detection

- Level Detection in Vessels

- Carton Dimensioning

- Detection of Transport Containers

- Success Stories

- Clear Container Detection

- Correct Label Verification

- Detecting Different Size Packages on a Conveyor

- High-Speed 2D Barcode Inspection

- Multicolored Reflective Package Detection

- Plastic Roll Diameter Measurement

- Tube Positioning Using a Registration Mark

- Vertical Form Fill Seal Machine Solutions

- Pharma

- End-to-End Sample Tracking with RFID

- RFID Control of Tube Connections in the Ex Area

- Decentralized Package Verification

- Automate Modular Skids

- High-Speed Tablet Counting With DF-G2

- Pharmaceutical Skids with Decentralized I/O Technology

- Ex Isolation in Modular Process Plants

- I.V. Bag Liquid Detection

- Control of Valve Interfaces

- Monitoring of Quarter Turn Actuators

- Detection of Pipe Elbows

- Remote Signal I/O

- Planning and Construction of Super Skids

- Liquid Level Monitoring

- Easy Connection of Field Devices

- Identification of Cryovessels

- Identification of Mobile Containers

- Identification of Mobile Containers with Handheld Devices

- Identification of Hose Connections for Precursors

- Identification of Hose Connections in Sterile Areas

- Identification of Hose Connections in Ex Zone 1

- Identification of Big Bags and Bioreactors

- Identification of Single-Use Applications

- Success Stories

- Semiconductor

- Electronic Marking Verification

- Counting Integrated Circuits

- Inspection of Two Barcodes

- Compact Safety Control

- Safeguarding Small Access Points

- Semiconductor Process Tool Illumination

- Adhesive Detection on PCB Assembly

- Wafer Center Detection with DF-G2

- Great Detail Inspection for Mobile Electronic Devices

- Error Proofing for IC Chips loaded into Pocket Tape

- Presence and Orientation of IC Chips Seated in Nests

- Detection of Hard Disks

- Multiproduct Light-Guided Assembly Station

- LED Status Indication During Semiconductor Manufacturing

- Safeguarding Small Access Points

- Success Stories

-turck-image.jpg)

-turck-thumbnail.jpg)