Track and Trace Solutions

Comprehensive RFID Platform for Traceability Across the Entire Supply Chain

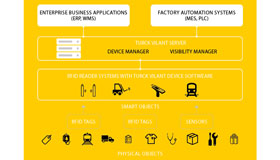

Turck Vilant Systems delivers turnkey track & trace solutions for manufacturing, logistics and healthcare customers worldwide. The in-house developed track & trace platform comprises an intelligent RFID system. In addition, it expands to utilize active tracking elements, such as BLE, GPS, or other IoT equipment when needed.

The platform includes RFID middleware for different read points and an RFID server on-premises or in the cloud for data mining, system maintenance and integration with enterprise IT systems such as ERP and WMS. In this way, work floors, stock rooms, dock doors, forklifts, mobile devices, and conveyor belts can be outfitted with RFID technology to monitor documents, assets, materials, finished products, boxes, roller cages, or pallets.

The RFID solution meets the industry standards defined by GS1 and provides ready-to-use components for all common RFID applications.

Elements of the RFID Turnkey Solution

The Turck Vilant Server applications collect, consolidate, control and mine data from different RFID read points as well as control and monitor the health of individual readers and read points.

- RFID tags, which can be attached to or embedded in the objects to be identified

RFID read points and their antennas, which interact with the tag without requiring a line of sight - RFID server applications (cloud or local) for data mining and system health and maintenance including an integration layer with support to most common business systems such as ERP and WMS

- Integration to the customer’s backend system

- An implementation plan

System Management by RFID Server Applications

The RFID server is at the heart of the RFID system and it has two main functions: RFID data management and system health and maintenance. The primary functions of the RFID data management application include data consolidation from data collection applications, integrations to business systems and reporting. Different RFID use cases are served by different RFID read points such as printers, gates, forklifts, conveyor belts and handhelds.

System health and system maintenance is handled by the Turck Vilant Device Manager. The application acts as a device manager and manages the entire RFID system. The RFID devices serving different RFID touch points are all connected to it. Each customer location and each individual device on that location can be monitored and accessed remotely from the device manager. This means that printers, gates, forklifts, conveyor belts or handhelds can be seen and their software updated when necessary. Both applications have a web-based user interface and offer flexible user management.

Turck Vilant Systems Production Tracking Solutions

RFID Enables Unmanned Store at Major Building Site

Using an RFID system solution from Turck Vilant Systems, wholesaler chain ProMart developed the “EasyMart” shop concept – self-service containers or store rooms that make fixing materials and tools available at any time and on any site

RFID: ROI Achieved After Three Avoided Delivery Errors

For a plastic pipe manufacturer, the RFID solution for the comprehensive control of loading and delivery processes pays off after just three delivery errors are avoided

Sustainable Tracking of RTIs thanks to RFID

Logistics services provider Recalo monitors its pool of returnable transport items (RTI) with a track and trace solution from Turck Vilant Systems and thus reduces its customers' CO2 footprint

RFID Solution with Smart Forklifts in Autombile Production

RFID solution with smart forklifts and IT integration via middleware from Turck Vilant Systems ensures reliable and fast goods flows in Chinese automotive plant

Tracking Big Bags with RFID

Extensive control over the production and delivery process of assets as well as full compliance with legal requirements

Shipment Tracking for Raw Materials

Material transparency called for Sandvik to introduce an automated inbound processes with RFID

RFID-based Shipment Control Minimizes Errors

Jysk ensures delivery accuracy by fully automated tracking of position and direction movement of outgoing pallets

RFID-based Tracking of Inbound and Outbound Materials

ABB realizes 60 percent productivity growth by digitalizing their production including material flow tracking with an UHF-RFID system directly linked to the company’s SAP

End-to-End Sample Tracking with RFID

RFID-based solution ensures consistent sample management, real-time monitoring, and maximum data integrity while reducing human error and enhancing efficiency

- Topics & Technologies

- Asset Monitoring Gateway with Cloud ID

- Asset Monitoring Gateway with SNAP ID

- Codesys

- Condition Monitoring

- Ethernet in Hazardous Locations

- Field Logic Controller

- Industrial Cloud

- Industry 4.0

- IO-Link

- Machine Safety

- Modular Machines

- Module Type Package

- Multiprotocol Ethernet

- Pick-to-Light

- Profinet

- RFID

- Safe work and Occupancy Monitoring

- Snap Signal

- Sustainability

- TAS – IIoT Service Platform

- The Visual Factory